1. Weld flange kune pombi uye kutonhora kusvika kune ambient tembiricha usati waisa vharafu kune flange.Zvikasadaro, tembiricha yepamusoro inogadzirwa newelding ichakanganisa kuita kwechigaro chakapfava.

2. Mipendero yewalded flanges inofanira kuiswa kuti iite seyakatsetseka kuti isakuvara kwechigaro chakapfava panguva yekugadzwa kwevharuvhu. Iyo flange yepamusoro inofanira kunge isina zvachose kubva pakukuvadzwa uye deformation, kubvisa tsvina yese, guruva uye kunze kwenyika, uye kudzivirira kubuda kwemvura kwevhavha uye. flange interface.

3. Chenesa flange uye mukati memugodhi wepombi kuti ubvise zvachose sputter, chiyero uye mimwe miviri yekunze yakasiiwa newelding.

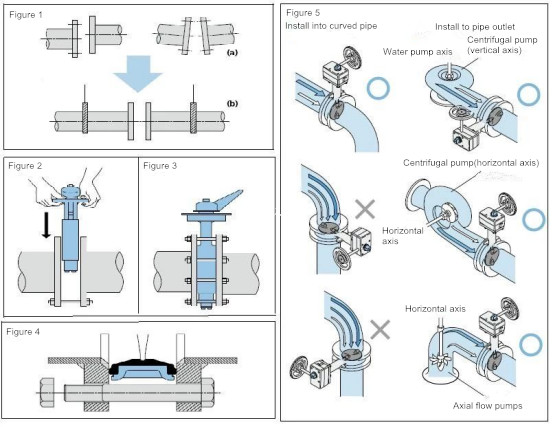

4. Paunenge uchiisa pombi pakati pemavharuvhu, kurongeka kwakarurama kwepakati pemitsetse yemvura yepamusoro uye yepasi kunokosha pakushanda kusina matambudziko.Iyo nzvimbo isina kunaka yepakati inoratidzwa muMufananidzo 1 inofanira kudziviswa.

5. Paunenge uchiisa valve, gadzirisa mabhoti ekuisa pasi pepombi pahupamhi hwakafanana kuti uite basa rinotsigira, uye gadzirisa kureba pakati pemafurati kusvikira mativi maviri emuviri wevhavha ari anenge 6-10 mm. Yeuka kuti valve inogona kuvhurwa chete kubva panzvimbo yakavharwa kusvika kune 10 ° nzvimbo.

6. Isai mabhoti maviri muchikamu chezasi chevhavha uye isa zvakanyatsonaka kuitira kuti flange irege kukuvadza chigaro chinyoro.6.(ona mufananidzo 2)

7. Zvadaro isa mamwe mabhaudhi maviri mugwara rekutungamira pamusoro pevharuvhu, kuve nechokwadi chepakati penzvimbo pakati pepombi nevharuvhu.

8. Vhura vharafu katatu kuti uone kana kusangana pakati pevharuvhu ndiro uye flange haina kutsvedza.

9. Bvisa mabhoti ekugadzirisa uye uise mabhoti ose kumativi ose emuviri mukutsinhanisa diagonal tightening (ona Fig. 3 uye 4) kusvikira flange inobata muviri.

10. Ipa tsigiro yevhavha paunoisa actuator kuti udzivise kumonyoroka kwemutsipa wevharuvhu uye kuderedza friction pakati pevharuvhu nepombi.

11. Usatsike pamutsipa wevharuvhu kana vhiri reruoko.

12. Usaisa DN350 kana mavharuvhu makuru akatsikitsira pasi.

13. Usaise mavharuvhu eshavishavi pacheki mavharuvhu kana pombi sezvo izvi zvinogona kukuvadza kana wasangana neplate yevharuvhu.

14. Usaisa mavharuvhu kudivi rezasi remagokora uye tapering tubing, kana calibrate mavharuvhu kana kuyerera kwemazinga kuchichinja. Muchiitiko ichi, zvinokurudzirwa kuisa valve pachinhambwe chingangoita ka10 dhayamita yezita revhavha.

15. Kuiswa kwevharuvhu kunoda kutarisisa kuti ndeipi disc inosangana nekuyerera uye kudzvanywa panguva yekuendeswa kwemvura.

Nguva yekutumira: Sep-17-2022