Mafuta ekutamisa kupisaimhando yemafuta akakosha ane kugadzikana kwakanaka kwekushisa kunoshandiswa kune isina kunanga kupisa kupisa.Heat conduction mafuta haingogone chete kusangana nezvinodiwa zvekudziya uye kutonhora kwemhando dzakasiyana dzetembiricha muhupamhi hwetembiricha, asi zvakare kuziva zvinodikanwa zvekupisa tembiricha yekupisa uye kutonhora kwakadzika kwekushisa nemafuta akafanana ekupisa mune imwecheteyo system, inogona. kuderedza kuoma kwehurongwa uye kushanda.Naizvozvo, kupisa conduction mafuta ekudziya system inoshandiswa zvakanyanya mumakemikari fiber, zvinhu uye mamwe maindasitiri.

Hunhu hwekupisa conduction oiri system:

1.Pasi pemamiriro ezvinhu anenge emhepo, inogona kuwana yakanyanya kupisa tembiricha yekushanda - ndiko kuti, inogona kuderedza zvakanyanya kudzvanywa kwekushanda uye kuchengetedzwa kwezvinodiwa zvekushisa kwekushisa kwepamusoro, kuvandudza kuvimbika kwegadziriro nemidziyo;

2. Iyo inopisa-inobata mafuta ekudziya system inosiya iyo yekurapa yemvura sisitimu nemidziyo, iyo inovandudza kupisa kweiyo sisitimu uye inoderedza basa rekuchengetedza remidziyo nemapaipi - ndiko kuti, mari yekutanga uye mari yekushandisa yekudziya system inogona. kuderedzwa.

Njodzi dzinogona kuitika dzekupisa kwemafuta system kuita:

1.Nekuda kwekupisa kwenzvimbo yekupisa kwekushisa panguva yekushandiswa kwemafuta ekupisa-kupisa, kupisa kunopisa kunowanzoita kuitika, zvichiita kuti pave nemhepo inopisa uye yakaderera-flash point oligomers.Polymerization pakati pe oligomers inogadzira isinganyungudika uye isinga nyungudika mapolima, ayo asingangotadzise kuyerera kwezvigadzirwa zveoiri uye kuderedza kufanana kwekupisa kwekuita basa, asi zvakare kunokonzeresa mukana wekupisa kwekupisa kwenzvimbo uye kuputika kwepombi.

2.Kupisa mafuta ekufambisa uye kunyungudika kwemhepo uye kupisa kwekutakura system kuzadza ndiyo oxidation reaction yemhepo yakasara pasi pemamiriro ekupisa, uye kuumbwa kwe organic acid uye colloid inonamatira kune pombi yemafuta, iyo isingangokanganisa hupenyu hwebasa rekupisa kupisa kwepakati uye. inovharira pombi, asi zvakare inokonzeresa kukora kweasidhi yepombi uye inowedzera njodzi yekubuda kwehurongwa hwekushanda.

Tsaona dzekupisa kupisa mafuta ekudziya system dzinosanganisira:moto wekupisa tangi yekupisa, moto wekuwedzera tangi yekubuda uye yekupisa yekupisa, moto wekutamisa mafuta system system yekushanda, moto uye kuputika kwekupisa kutamisa mafuta ekuchengetera tangi, moto uye kuputika kwekupisa kwemafuta ekupisa kupisa kana reactor (kettle), kuputika kwechoto, etc. Zvinogona kuonekwa kuti dzakawanda dzinowanzopisa mafuta ekupisa hurongwa hwetsaona dzine chokuita nekudonha.

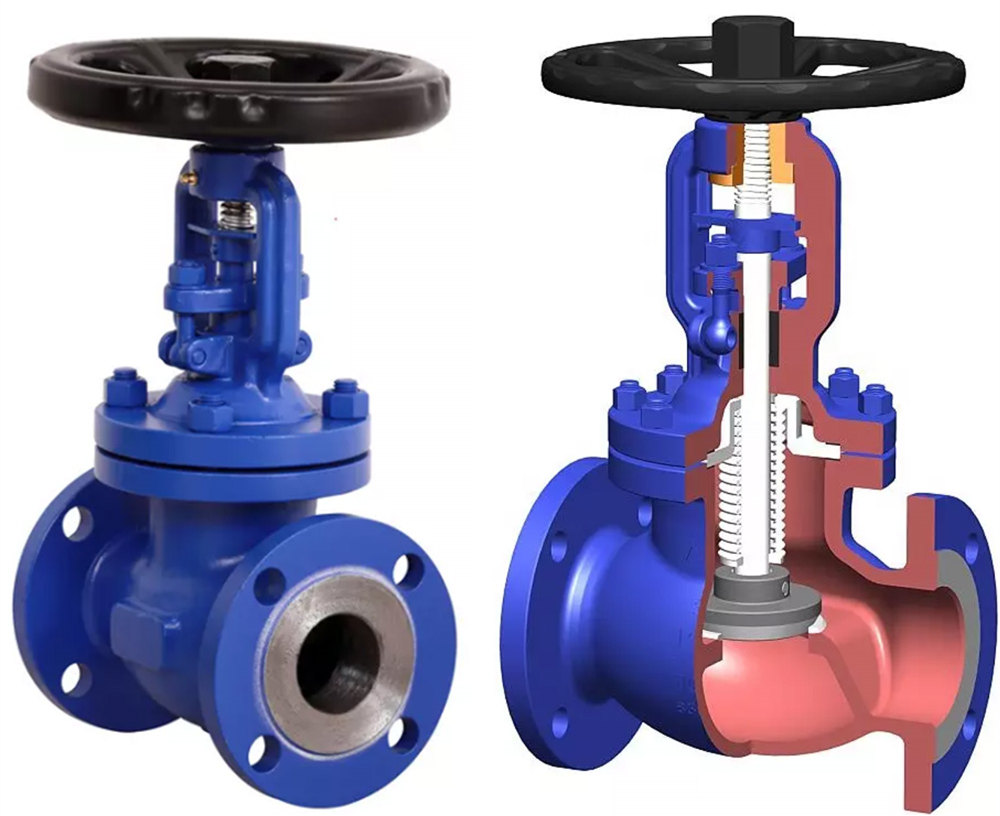

Valve zvinodiwa zveyakajairwa tekinoroji uye dhizaini maratidziro mune inopisa mafuta masisitimu anosanganisira: an kubuda vharafupanzvimbo yakakwirira uye vharafu inoputika panzvimbo yakaderera.Mutsara wepombi weiyo inopisa mafuta system inofanira kubatanidzwa nayoflangeskunze kwenzvimbo dzekushandisa, nzvimbo dzekushandisa kana mavharuvhu.Mamwe mainterface ese ane welded.Theflangeinofanira kusetwa groove pamusoro, uye iyo yezita kudzvanywa haifanire kunge iri pasi pe1.6MPa.Kune kupisa conduction mafuta ane tembiricha yakakwira kupfuura 300 madhigirii, iyo yezita kudzvanywa kweflangehaifanirwe kunge iri pasi pe2.5MPa.Flangesanofanira kunge ari butt welded pane flat welded flanges.Iyo flange gasket yeanopisa oiri system haibvumidzwe kushandisa asbestos rabha ndiro, simbi inotenderedza pad kana yakawedzera graphite composite pad inofanira kushandiswa.Iyo inopisa mafuta system inofanirwa kupihwa nevhavhavhavha yekuchengetedza, uye vharafu yekudzivirira inofanirwa kunge iri mabhero akavharidzirwa evhavhavhavha.

Iyo yevhavha yemafuta anopisa system haifanirwe kukandwa simbi kana isiri-ferrous simbi.Tichifunga nezvekudzikira kwayo, tembiricha yakakwira uye kupera kwakanyanya kusimba, zvinoenderana neyakajairwa tekinoroji dhizaini, pombi inopisa yemafuta yakachekwa vharafu inofanira kushandisa mabhero seal yekucheka-vharavhavhavhavha, inogadzirisa vharafu inofanira kushandisa mabhero seal sleeve yekudzora vharafu, kuchengetedza vharafu uchishandisa. yakazara yakazaruka mabhero chisimbiso chekuchengetedza vharafu.

Nekuda kwehunhu hweoxidation kugadzikana kwemafuta ekupisa conduction, kuvuza kwevhavha yemafuta inopisa hakungokonzereri kupisa kwechivharo chekudzivirira kana kupisa uye kuputika kwemidziyo, asi zvakare kukonzeresa kuita kweiyo oxidation yekupisa conduction mafuta uye mhepo yakanyungudika mumhepo. nyaya yekupisa, inogadzira organic acid corrosion valve internals.Saka vheji yemafuta inopisa haifanire kungoita kusabuda kwemukati, asiwo usaite kubuda kwekunze.

General packing globe valve packing ne graphite processing molding, kana kuchena kwegraphite kusina kukwana, mafuta ayo anopikisa achava akaipa kwazvo, apo kupisa kwemafuta ekupisa mukati me graphite kurongedza, mamwe matsvina mu graphite ari nyore kunyungudutswa nekupisa conduction. mafuta, zvichiita kuti graphite upfu, haigoni kuita graphite kurongedza kuti kuzadzisa chisimbiso kushanda, ichi ndicho chikonzero chikuru packing vharafu kazhinji kubuda.Iyo bhero seal inodzivirira kusangana kwakananga pakati pemafuta anopisa uye graphite, iyo inogadzirisa dambudziko remafuta anopisa anodonha kubva pahunde kana graphite packing yanyungudika.

Nekuti kupenya kwemafuta ekupisa ekupisa kwakasimba kwazvo (inenge 50 nguva yeutsi), kana chisimbiso chekuzadza chasarudzwa, zviri nyore kubuda kunze, zvichitungamira mukuraswa kwemafuta anopisa, midziyo yakasviba uye pasi, uye chimiro chebhero. inogona kunyatsoona zero kuvuza, uye hapana kupfeka zvikamu.

Nekuda kwengozi inogona kuitika yeoxidation kugadzikana kwemafuta ekupisa, zvikamu zvemukati zvevharuvhu zvakagadzirwa nesimbi isina tsvina, iyo inogona kumira 425 ℃ yakakwirira tembiricha, corrosion resistance, uye switch iri nyore.

Kubva pakuona kwehupenyu hwese, hupenyu hwebasa remukurumabhero sealing valveiri nani pane mamwe mavharuvhu.Mafuta ekutamisa kupisa ane high viscosity uye yakakura kuyerera kuramba mukutonhora.Iyo yevhavha yepakati inotora inokurumidza kuvhura mhando, iyo inogona kuvandudza kuyerera uye kukurira kuyerera kwekupokana kana uchitanga.Nokudaro, kuitira kuti tive nechokwadi chekugadzikana kwekugadzirwa, asiwo kuti kuderedze mutengo chaiwo wekushanda, kupisa kwemafuta ekufambisa mafuta kunofanira kusarudza kukurumidza kuzarura valve yepakati.Bellows seal stop valve, haigone kusarudza iyo yekurongedza seal yekumisa vharafu kana general valve.

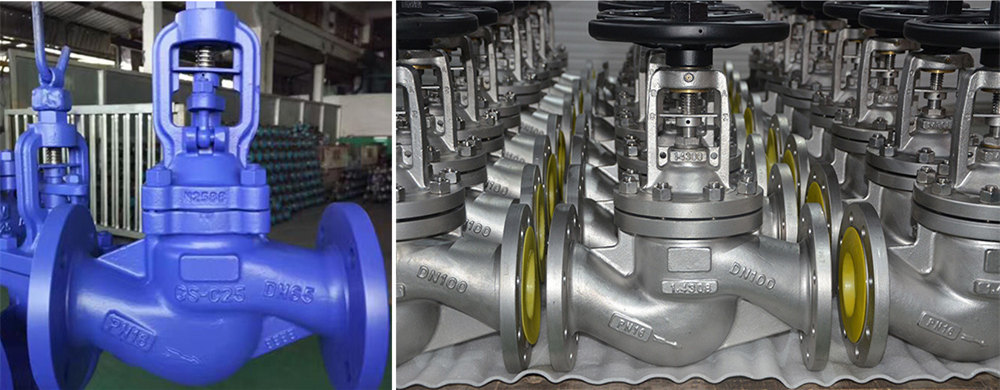

Bellows sealing globe valveinogadzirwa neBESTOP yakanyatsokodzera kucheka pombi yekufambisa yemafuta anopisa system.

Nguva yekutumira: Jan-29-2023